Network Department

Mesh features: the top mesh dehydration configuration, increase the dehydration capacity, surface core layer forward composite to improve the forming uniformity. Function: a certain concentration of slurry through mechanical and chemical action to form a certain unit area weight of wet paper.

Applicable to various parts of the net scraper type and use recommendations

In order to achieve a good cleaning effect and at the same time protect the roller surface from damage to the greatest extent, according to the different materials of each roller surface, blades of different materials and metal roller surface are selected. Generally, blades made of carbon fiber are selected. The rubber roller can use ultra-high molecular weight polyethylene UPE scraper. We use imported raw materials with 7.2 million molecular weight for production. InWear resistance, cleaning effect, self-lubricating, corrosion resistanceandanti-adhesionsignificantly higher than the traditional HDPE polyethylene scraper. Of course, you can also use carbon fiber blades or glass fiber blades. If you use these two material blades, you must pay attention to the change of the fixture, that is, the angle between the blade and the roller surface,

Maintain a scientific and reasonable cleaning angle, which is generally20 to 25 degrees.

For the rubber roller of the net part, we recommend use UPE (ultra high molecular weight polyethylene) cleaning blade with a molecular weight of more than 1.2 million. The WEIHAI JBEIK NEW MATERIAL CO. , LTD UPE cleaning blade is produced from imported raw materials with a molecular weight of 7.2 million. Compared with the HDPE (high density polyethylene) cleaning blade whose molecular weight is not more than 500000, the wear resistance and temperature resistance are significantly improved.

The characteristics of UPE are: ultra-high molecular weight, high lubricity, high wear resistance, while cleaning the roller surface, the protection of the roller surface is not scratched.

The recommend is used on the specific rollers of the web pressing part, such as the guide roller of the web part, the expansion roller, the correction roller, etc. Generally 20 to 25 degrees.

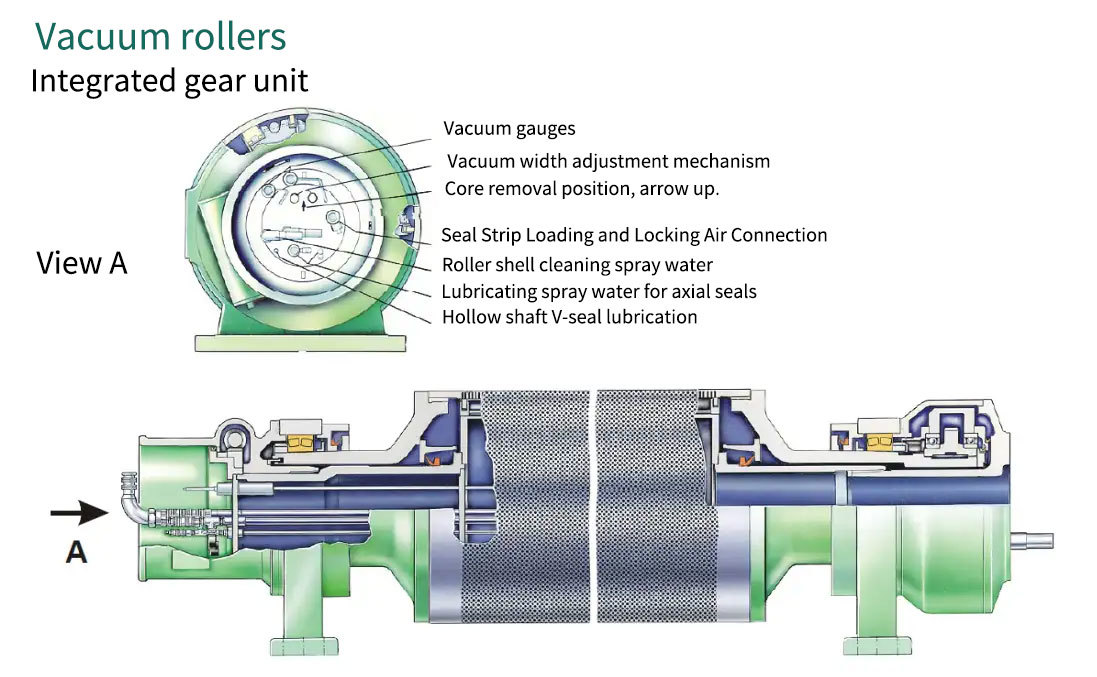

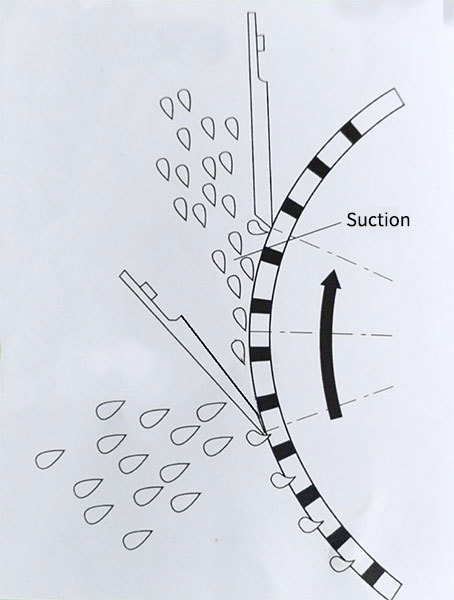

For the two scrapers of the vacuum roller, it should be noted that the cutting edges of the two blades are opposite to each other. The function of the two scrapers is that the cutting edge of the first scraper is in close contact with the roller surface, so that the contact part of the roller surface and the cutting edge of the blade forms a negative pressure instantly, sucking out fine fibers and foreign matters in the pores of the roller surface. At the same time that the second scraper cleans the roller surface, scrape off the things sucked out by the first scraper together. Therefore, these two scrapers should be noted when applying for the plan and should be paid attention to when installing.

| Roller | Material | |

| Mesh Department |

breast roll breast roll Net offset correction roll Return roll vacuum roller vacuum roller Inner guide roll Outer guide roll Upper screen roll

|

Rubber, resin roller BC Rubber, resin roller Rubber, resin roller SUS lining Rubber, resin roller Rubber, resin roller Rubber, resin roller Rubber, resin roller |

Key words:

Application Products