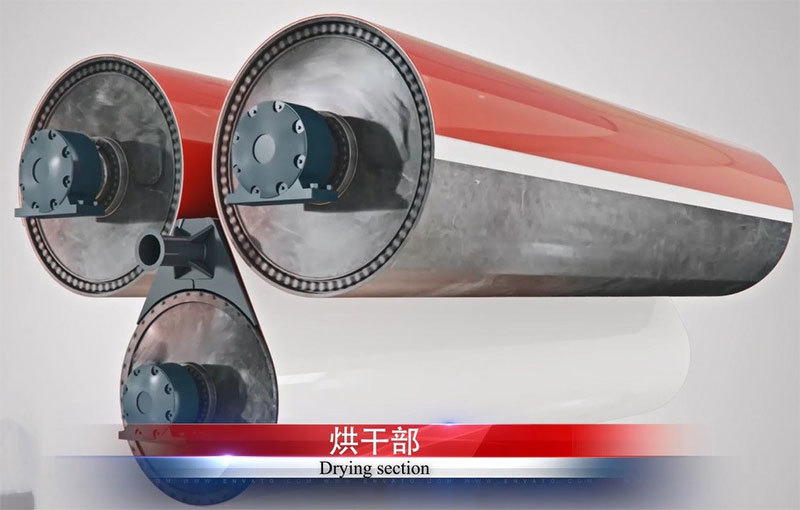

Drying Department

The dry degree of the wet paper web from the press section is only 40%-50%, and a part of the water is evaporated by drying, so that the dry degree of the paper web reaches about 92%. The drying section consists of a number of drying cylinders and guide rollers and a dry web, and the wet paper web is dried as it passes through the drying section.

Before baking

Before baking

At present, most of the raw materials in the paper mill are national wastes. Due to the high humidity of the paper sheets in the front dryer, the accumulation on the surface of the front dryer is large and hard, which is very difficult to clean. There is an urgent need for materials with high hardness and smooth surface that are not easy to adhere to the accumulation.

The current solution is: spray tungsten carbide on the cylinder surface first, spray tungsten carbide into particles, spray Teflon to seal the particle gaps of tungsten carbide, and finally grind off the excess Teflon with a grinding scraper. The cylinder surface has the hardness of tungsten steel and the friction coefficient is extremely low (the main component of Teflon cylinder surface is still tungsten carbide).

Advantages and role:

① Reduce the accumulation of glue. ② Reduce the number of broken paper.

The heat transfer is higher. ④ The dry net is less worn.

⑤ The service life is more than 5 times that of ordinary chrome cylinder.

⑥ Reduce the wear of the scraper blade and the amount of stripping agent used.

The disadvantages are:

The cost is high, the general packaging paper factory will choose 1~3 cylinder spraying.

Cleaning of front group dryer

Solution-"hard and soft" cleaning method

"Gang" is a phosphor bronze scraper (as shown in the right figure) with tungsten carbide sprayed on the blade developed and produced by WEIHAI JBEIK NEW MATERIAL CO. , LTD. Using this kind of blade to quickly clean the "nail house" on the cylinder surface has an immediate effect. Using a carbon fiber scraper with high carbon content to clean the remaining impurities and foreign matters on the cylinder surface becomes much easier. It is suggested that tungsten carbide copper scraper and high carbon fiber content scraper should be used alternately to clean the roller surface better.

When using ceramic alloy scraper to clean the surface of the dryer, it may cause the risk of sparks and damage to the cylinder surface. When using, please pay attention to the following four points:

① Don't leave people when working and observe at any time.

The cleaning time is as short as possible (10-20 minutes).

③ Pay attention to adjust the loading pressure (reduce the loading pressure).

④ Adjust the angle of the scraper (lower the cleaning angle).

It is more normal for the composite blade to have slight delamination, cutting edge and crack in the front dryer.

Due to the repeated recycling of national waste in papermaking, the fibers are getting shorter and shorter, and chemical raw materials need to be added to make up for the short version of the fibers. In addition, there are too many adhesive tapes and so on in the front dryer (especially in cylinders 2 and 3, which is much better because cylinder 1 has stripper). It is difficult to clean too much adhesive. In addition, the temperature of the dryer is too high to dry the adhesive that is not removed in time, under the impact of high speed, the carbon cloth on the outermost layer of the blade close to the surface of the dryer is broken and deformed. At the same time, the hard sundries break the outermost layer of the blade and fall off. This is not a blade quality problem. This is a common problem of waste used by domestic paper mills. Our company is actively solving it!

In view of this problem, our company suggests to use WEIHAI JBEIK NEW MATERIAL CO. , LTD alloy ceramic copper scraper to clean the front dryer (because it is a metal blade, our company's technicians are required to go to the site to evaluate and issue a technical scheme according to the working conditions before use)

After baking

Suitable for drying each part of the scraper type and use recommendations

It is recommended to use a carbon fiber scraper with a content of 20%-40%, which is the most cost-effective. Due to the characteristics of carbon fiber, the cleaning effect and protection of the cylinder surface are the best.

When installing the knife body at the drying part, adjust the angle to 25-28 and control the linear pressure to 200 g/cm. Left and right

The dryer of the paper machine is very critical and important. We are developing blades for cleaning the dryer. 1. Consider the temperature resistance of the blade, 2. Protect the cylinder surface without producing black lines, 3. The cleaning effect, the last one is wear resistance, we develop suitable blades according to the roller surface of different materials and requirements

| Roller | Material | |

| Dryer section |

Dryer dry screen roll gate roller SIZE Press Roll |

Heat resistant NBR Rubber, resin roller carbon fiber 100 K-500 |

Key words:

Application Products