Upper and lower round scraper

- Commodity name: Upper and lower round scraper

- Product Description

-

High strength can be customized

Using high-carbon high-alloy tool steel, more excellent performance, customizable products, more convenient to use

Product model information

upper round knife

Material: W6Mo5Cr4V2 commonly known as "front steel"

Rockwell hardness: HRC63-64

It is a high-carbon high-alloy tool steel suitable for high-speed cutting.

High hardness, good thermal stability, good wear resistance

Lower round knife

Material: blade insert tungsten alloy

Rockwell hardness: HRC85

Widely used in JG, aerospace and other industries

Hard texture, good abrasion resistance

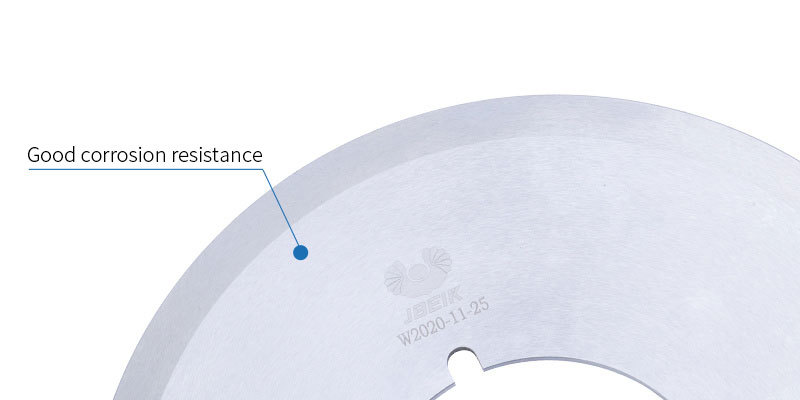

Aviation grade high carbon high alloy

Aviation-grade high-carbon high-alloy tool steel to ensure that the product is excellent for use on paper machines, clean and energy-saving

High temperature resistance up to 190 ℃

Adopt advanced heat treatment process to improve the stability of the round knife and improve the service life

Special Scraper Blade

|

|

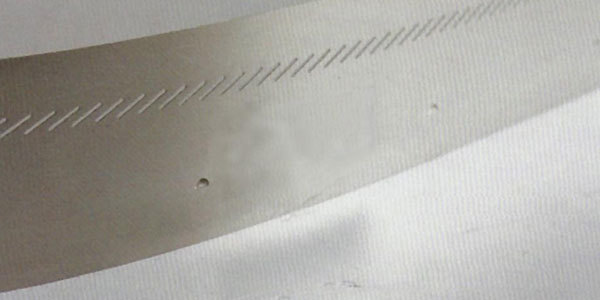

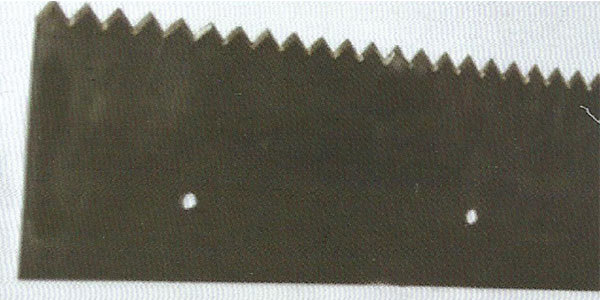

| Sealing scraper blade | toothed scraper blade |

| Advantages: selection of domestic high-quality stainless steel processing, can be produced according to user requirements | Advantages: selection of domestic high-quality stainless steel processing, can be produced according to user requirements |

Ceramic alloy coated doctor blade

Features

Super wear-resistant, continuous operation, high cost performance, greatly improve paper and output

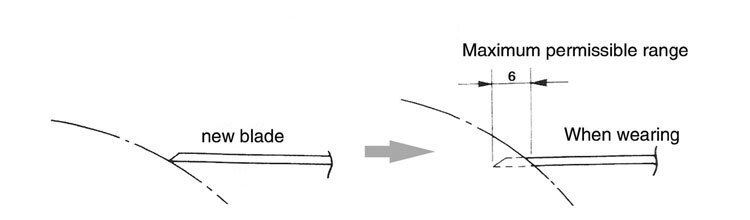

Service life of the blade

The blade and the rotating roller rub for a long time, and the blade wears more. The service life of the blade has a lot to do with the material of the blade, the correct use of the blade, the material characteristics of the roller, and the amount of foreign matter on the surface of the roller.

Some paper machine special roller, 1.5mm wear will need to replace the blade, such as continue to use, the following problems may occur:

1. Damage to the roller

2. Vibration in front of blade

3. Roller foreign matter is not completely clear

Key words:

More products